In short:

The installation of two UR10 robots at PLC Industries’ production site in Singapore has boosted output by 40% without hiring more people. Thanks to the flexibility of the robotic arms and the minimal supervision required one worker can now attend to four CNC machines.

Payback period:

12 months

Challenge:

Shortage of skilled labour coupled with rising material and real estate costs have become huge issues for companies in Singapore. PLC Industries – a service provider in precision engineering – decided that automating their production lines would help meet the challenges and began the process in early 2014.

As safety is a top priority one of the main concerns was that the layout of the production line required workers to be in close proximity to the robots. Management wanted to ensure that the selected robots were able to operate efficiently and safely within confined spaces.

Solution:

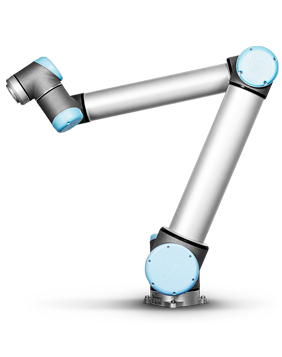

Upon completing the necessary risk assessments, PLC Industries received confirmation that the UR10 robots do not need safety guarding and invested in two UR10s.

“Seeing my colleagues being totally at ease working alongside the robots is very encouraging. Being able to work without fear is a definite plus for all of us. The improved focus that everyone now posseses comes from lower fatigue and higher concentration levels. This significantly reduces the chance of an accident from occurring”, says Yeo Hock Lee, Engineering Manager at PLC Industries.

Another UR10 feature that proved valuable to PLC Industries is the easy programming. Due to space constraints and a lack of manpower it was essential that each robot would be able to serve two CNC machines. Thanks to the flexibility of the UR10, a single worker can now attend to four CNC machines – which has boosted output by 40% and increased production variety.

Product: UR10

Share and recommend